Damaged pallet racking is a major component when it comes to managing your supply chain — preventing, maintaining, and fixing damaged pallets, crates, wood packaging, and other tools within your warehouse is a 24/7 job. If you don’t take it seriously enough, it may cause serious safety issues and can affect the timeliness and quality of your operations. In this article, we’re going to give you some pro-tips on how to prevent pallet rack damage and what you can do to have a more cost-effective warehouse.

Common Pallet Rack Damage

A damaged rack pallet, and the cost associated with them, has more to do with how said deterioration compromises your ability to perform and have a more effective warehouse, than the aesthetics associated with the blemish.

Compromised pallets and their racks carry potential risks — risks to the products they are transporting or storing, as well as risk to your personnel and your staff. Failure to properly take into consideration a damaged pallet rack may end up hurting you a lot.

Some of the most common pallet rack damage comes from:

- Excess weight: putting too much weight on a pallet or its respective rack can result in damage to deck boards and stringers.

- Pallet jack damage: if an operator tries to lift the pallet jack while it is on the bottom boards it will crack.

- Forklift: 70% of pallet damage comes from faulty handling by a forklift driver. They can strike the caller with the fork at the entry boards or against racks.

- Dropping the pallet: dropping the pallet, and allowing gravity to take hold, will crack and splinter it.

- Using wrong pallets: each material, or product, needs different pallets. Food items that need to be stored at freezing temperature, for example, need boards and woods that can withstand said temperature.

- Climate damage: whether it’s excessive moisture or extreme heat, it’s important to understand that 90% of pallets are made out of wood. Wood deteriorates over time, and that damage accelerates if it finds itself in a hostile environment — a workstation or warehouse that’s either too dry, too humid, too cold, or too hot. Rotted wood can then affect your steel or metal racks, rusting them.

How to Reduce Pallet Rack Damage

Pallet racks are constantly submitted to abuse. Even the sturdiest rack will eventually need a little love and care – maintenance. The best way to prevent damage is by cautiously handling and guarding your equipment. Steel pallet racking or metal pallet racking are subjected to multiple variables, including being hit by forklifts, impact from other machinery, or simply being mishandled by staff.

Here are some tips to help you avoid headaches and frustrations — not to mention expenses, injuries, and safety violations.

Widen Your Aisles

The main issue when it comes to protecting your pallet racks is the width of the aisle. Companies want to constantly maximize their floor space, and as such, use narrow aisles. This is counterproductive, as forklifts need room to maneuver. Most pallet rack inspections have revealed that 70% of accidents when it comes to racks, is a result of improperly using forklifts, and in many cases, this is simply because the space they needed to operate was too small.

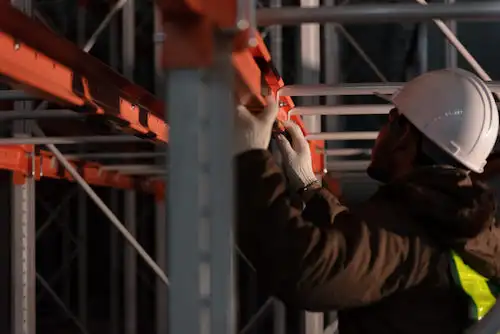

Install Guardrails, Pillars, or Other Protective Systems

Protect the corners — that’s one of the most important tips when it comes to preventing pallet rack damage. Install pallet protectors at each frame to help cushion against impacts. This will require a front-end investment, but over time it pays off in huge ways.

Don’t Skimp Out on Anchoring your Pallet Racking

Most people don’t know how to anchor pallet racks. In general, warehouse managers simply set them up but don’t take the time to bolt them to the floor. This is incredibly important and may mean the difference between small collisions and your pallet rack collapsing entirely to the ground — in such cases, you not only run the risk of injury but in all likelihood, you’ll lose thousands of dollars in damages.

This will obviously damage racks as well as the products being stored on them. That is why it is crucial to understand how to secure pallet racking. SRSI (link to our racking page) always ensures every rack frame is bolted in every project.

Good Lightning

While this can be seen as a minor issue, sufficient lighting is still one component that helps a lot. Improve your current lighting setup, particularly in the darker parts of your warehouse. Good lighting helps maintain safety, promotes attention to detail, and helps staffs’ state of mind — keeping them sharper on the job.

Inspect Regularly

The best tip we can give you, to prevent or minimize pallet rack damage, is to inspect them regularly by a qualified professional. Complete internal walk-throughs and visual inspection at least once a week. Damaged racks are ticking time bombs waiting to explode. Inspections can save you a lot of economical, moral, and legal trouble in the future. Safety is SRSI’s #1 priority. If you need an inspection on how your warehouse or distribution center is doing, give us a call today: 833-228-6902.

Skip to main content

Skip to main content