The CDC, in its COVID-19 safety guidelines for warehouses, recommends a 6-feet social distance between workers. Warehouses are also required to reduce person-to-person contact by adopting virtual meetings and digital inventory tracking methods.

Certain Covid-19 measures such as wearing masks and using PPE may only be temporary, but measures such as social distancing and sanitization will continue even after the pandemic. The distance may not be 6 feet as it is now but would continue in some form or the other.

COVID-19 has certainly taught our industry, as well as all other industries, the importance of sanitation, social distancing, and healthy precautionary practices.

Such measures will continue to prevent the spread of a future pandemic. They will also ensure employee safety against other viruses such as those of common flu and cold.

Employee safety is a top priority that employers must prepare themselves for, even after the pandemic subsides. Warehouses can prepare themselves to elevate employee safety levels and maintain social distancing using automated storage and retrieval system.

Advantages of Automated Storage and Retrieval System for Employee Safety

Preparing your warehouse for future norms is key to your business’ success. With certain Covid-19 guidelines set to become norms even after the pandemic, there is no better time to prepare than now.

There are significant changes that your business may need to make to adapt itself for post-pandemic success. One of these being the integration of automated storage systems in warehouses.

Automation has been a part of warehousing for quite some time now, but a post-COVID world will accelerate its adoption. Processes such as real-time inventory adjustments, space management, and speedier order fulfilments will greatly benefit from automation.

The advantage that would propel the adoption of automated warehouse storage systems is their ability to facilitate social distancing and improve worker safety.

What is an Automated Storage and Retrieval System?

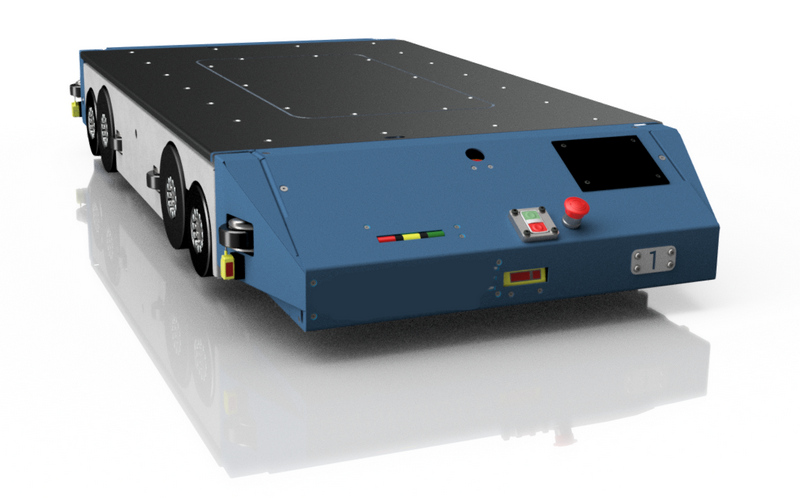

Automated Storage and Retrieval systems consist of equipment and controls, which can be computer-controlled for material storage, handling, and retrieval. Also referred to as AS/ RS or ASRS, these systems are faster and precise at task handling.

In action, an AS/ RS system can retrieve materials from defined locations and store them at required positions. ASRS can range from small, automated machines to large computer-controlled equipment. They can be integrated into whole processes such as manufacturing or distribution.

Unit-load systems, VLMs, shuttles (see RAFT for SRSI’s unique solution), and vertical/ horizontal carousels are examples of AS/ RS systems.

Here are some ways in which an automated storage and retrieval system can help warehouse managers increase efficiency and performance while adhering to pandemic stipulations:

Creates Space for Implementing Social Distancing

Social distancing needs space. If workers need to be apart, a facility must make space for it. Maintaining social distancing in tightly packed environments such as warehouses may not seem possible.

But the AS/ RS system can show the way. Automated storage and retrieval systems save a maximum of 85+% floor space that would otherwise remain wasted. Without space optimization, warehouses may have to create space by moving alternate workstations farther. This results in space shortage and shutting down of some workstations, which dramatically decreases productivity.

ASRS systems enable space creation by tapping into overhead or vertical space. Secondly, AS/ RS such as automated rack storage systems are typically used for loosely packed materials. These systems feature technology that compresses items stored within a cell.

This compression capability increases volumetric efficiency, meaning more space is created by compressing items. It should be noted that AS/ RS offers the maximum storage density.

These features, in unison, enable AS/ RS systems to create more storage space, which leaves employers with greater space opportunity for impacting social distancing.

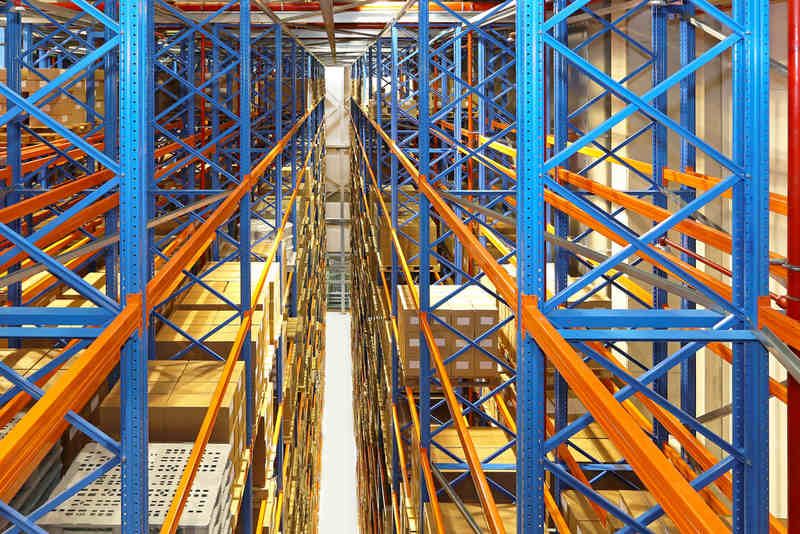

Enables Easier Implementation of Social Distancing

Warehouse operations need workers to be on site. Workers must keep moving around to get jobs done, so maintaining social distancing in such an environment can be challenging.

By facilitating social distancing, employers can reduce employee exposure to COVID-19. They can also be well-prepared to face a second or a likely third wave of the pandemic.

Businesses that fail to facilitate social distancing and other employee safety measures will more likely witness interrupted warehouse operations such as those observed during the lockdown. An inability to operate warehouses as per Covid-19 guidelines can result in facility shutdown. This, in turn, can cause excess inventory or a shortage of it and impact order fulfillment.

With AS/ RS systems, implementing social distancing becomes easier.

As AS/ RS are automated machines, minimal human intervention is required. Facility floors may be divided into work zones. A single worker can be assigned to each work zone. A work zone may consist of multiple automated storage system units.

Each work zone can be distanced from the other with the required space (for example, 6 feet currently). For even greater safety, dividers can be used between workstations. SRSI partners with the top vendors for custom workstations with partitions perfect for warehouses and distribution centers.

Makes Disinfection of Work Areas Easier and Efficient

As workstations are designated and spaced in between, sanitization becomes more of a focus than a random task as can happen with a crowded and unstructured facility. With efficient sanitization, you elevate safety levels for your employees at the workplace.

Contributes to a Safer Workplace by Reducing Worker Intervention

Social distancing requires lesser people. AS/ RS can help achieve this goal as they are designed to reduce human intervention. Workers can pick a product by staying at their designated places, which reduces employees moving around in search of materials.

An automated storage system increases task accuracy by a maximum of 99.99+%. The system also makes tasks easier for workers as they can pick materials without walking, bending, stretching, or twisting. By doing so, AS/ RS systems protect the posture, joints, and muscles, of workers. Workers get less fatigued and more productive as a result. In fact, AS/ RS systems increase labor productivity by a maximum of 85%.

Employers can reduce worker strength for specific tasks, which in turn facilitates the implementation of social distancing in a more efficient manner. The additional resources can be assigned to other facility tasks such as cleaning and disinfection.

AS/ RS systems reduce labor, boost productivity in a shorter time, and save substantial expenses for businesses.

In Conclusion

Preparing your warehouse for new post-pandemic norms is essential. Automation using AS/ RS systems is one of the primary ways to get your business to adapt faster to the post-pandemic future.

Adoption of AS/ RS systems should not be an afterthought. Without proper preparation for the post-pandemic times, your warehouse operations, employees, customers, and ultimately your business can suffer. That is why SRSI is a perfect partner for your AS/RS planning, implementation, and post-project support.

Automated warehouse storage systems create space for social distancing and make tasks easier, less stressful, and safer for your employees. With the right AS/ RS system, you create a safer and compliant workspace with the premium of greater productivity and cost savings for your business. SRSI specializes in automation and AS/RS as well as the supporting systems, software, and solutions to supplement your project for optimal operations. Reach out to us today to start your warehouse or distribution center transformation today: [email protected]

Skip to main content

Skip to main content