Selective pallet racking is one of the most advantageous and easy to apply systems in the storage industry. It is a multipurpose racking tool that can adapt to multiple usages and markets. In this article, we’ll do a quick write-up on the 10 best benefits of a selective pallet rack — what they are, and, more importantly, whether or not it’s a right fit for your business and the vision you have for it.

What is selective pallet racking?

Selective pallet racking systems are used to optimize warehouse space by storing products according to the product type.

These systems can be used for a variety of purposes, but they are commonly used in distribution centres and warehouses to store goods. A selective pallet racking system is made up of racks that are divided into sections or zones that correspond to a certain type of product. The most common types of selective pallet racking systems are:

- Vertical Pallet Racks

- Horizontal Pallet Racks

- Slatwall Pallets Rack

- Storage Rack Systems

The system gains its portmanteau or name because it allows users to “select” any pallet load from the pallet racking system without the need to move them around. They are the most commonly used system in distribution centres and warehouses — fully utilizing warehouse floor space and optimizing worker time.

Let’s take a look at some of the advantages of its design and methodology.

Selective pallet racking benefits

The effectiveness of this dynamic and incredibly versatile system is manyfold — that is why it is one of the most convenient methods for storage in a warehouse that you can invest in. Regardless of your budget, your square meter, and your industry. Let’s dive right in and come to terms with some of these benefits.

Cost-effective

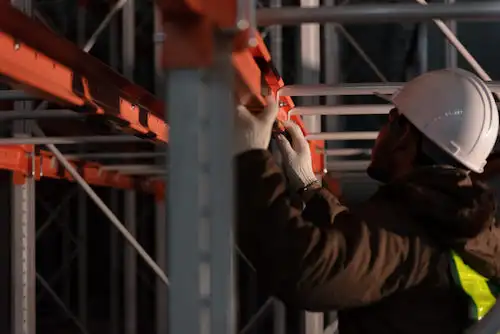

Selective pallet racking systems have an amazingly easy design to manufacture, install, and teach your workers on — it is incredibly inexpensive. Most sites consist of horizontal steel beans which are themselves connected to vertical still bends. That’s it. Two frames and the beams serve to craft a landing area where pallets can be added. Depending on your goods – the products you transport or hold – the racking system can be customized.

Accessories and sizes

Since selective racking systems are so easy to produce and have been in manufacture since storing goods became a trend, they have had the luxury of constant customization. This handing system has been tweaked, worked, and bedazzled with all manner of accessories. To put it bluntly, it’s one of the most pimped-out storage systems in the market — and size and add-ons are only limited by the user’s imagination.

Fits standard storage

Out-of-the-box, the base model, will fit and store most spaces, regardless of the size of your warehouse. With minimal labour, warehouses can ensure that every centimetre of space is being optimized as much as possible.

Easy installation

No special requirements needed or skills are needed to install a system of this magnitude. Regardless of your skill set or experience with a screwdriver. They can be constructed in a matter of minutes or days -depending on size – which further brings down costs.

Floor level

You won’t need an even floor to install a selective pallet racking system. This means you can adapt it to any environment with just a couple of simple modifications. These types of systems are used just about anywhere and that unique, simple, versatility affords it widespread in multiple industries.

Fast access

Selective pallet rankings systems provide users with immediate access to products. This system allows more than one forklift per aisle at a time — this makes it easier to keep up with your consumer’s demands and customer orders.

Different goods

It is one of the most effective systems because it can handle different types of goods — and can be acclimatized to different loads, heights, and weights.

Versatility

Selective pallet racking systems are one of the most customizable and affordable options in the market when it comes to storing goods. They can suit the needs of virtually any warehouse environment.

Multi-tasking

Since you can customize these systems, warehouses are more dynamic — they can expand their methodologies to include other tools besides forklifts, such as drones and robots, and can also section off the system focusing each section on a product or industry.

First In, First Out (FIFO)

It’s critical, when choosing a racking system, to evaluate your current inventory management system. By employing a FIFO – First in, First out system you can store large quantities of products at a time — using a selective pallet racking system will ensure that stock can be moved in the order it was received.

Who can benefit from a selective pallet racking system?

Most warehouses, despite their budget, or their industry – whether they are big, small, niche-oriented, or heavily financed – have a selective pallet racking system. They might lean heavily on other systems, on another tech, but this is a most. Why is that? Because they get the job done, are incredibly affordable, and in a pinch can store all sorts of items.

Skip to main content

Skip to main content